Solving Problems. Improving Reliability.

HRST strives to be the world’s most trusted supplier of HRSG and boiler related technical services and products.

HRST's 3-Step Solution: Inspect. analyze. solve.®

HRST’s engineers, technicians, and designers inspect hundreds of boilers each year. With experience across all major OEMs, we know where problems occur, what causes them, and how to solve them. Our integrated team doesn’t just find issues. We analyze root causes, simulate solutions, and deliver proven recommendations. From inspection and analysis to outage planning and on-site implementation, HRST provides clear, end-to-end support you can trust.

solutions

Our boiler design, field inspection and field problem investigation experience will help you solve and avoid problems. HRST boiler and pressure vessel design and retrofit services are certified by The American Society of Mechanical Engineers (ASME) and The National Board Inspection Code (NBIC).

Our Mission & History

Keeping the lights on

10 regional offices located in the United States. 2 offices in Mexico and Colombia. Representation in Australia.

Process Boilers

We specialize in technical services for Waste Heat Boilers (WHBs), Process Gas Boilers (PGBs), and Package Boilers for the power, refining/petrochemical, and process industries. Our team of engineers, technicians, and designers can inspect, analyze, and solve your facility’s boiler problems. We combine our experience from field inspection, engineering and design to analyze problems. We can understand how modifications affect system operation and determine component operating limits with our proprietary modeling software, HRST Performance Pro. Our engineering and design teams provide innovative solutions, and our technical field advisors provide expert guidance on repair work and installation.

OUR SERVICES

Inspection

We don’t just pin-point problem areas. We tell you why it’s there, offer recommendations to solve the problem and how to avoid it in the future.

Analysis

We perform engineering analysis to improve boilers and offer solutions to make your HRSG run more efficiently.

Covered Piping Systems

Covered Piping Systems (CPS), also known as High Energy Piping (HEP) is an ASME code-mandated maintenance item, due to the high risk for catastrophic failure on high temperature.

Field Services

Are you planning to purchase a new HRSG or need help reviewing a contractor’s boiler repair procedure? For any of your project needs, we have the experts to support it.

Training

Learn troubleshooting tips and design fundamentals by attending our HRSG Academy, or have personal on site training prepared for your specific plant!

OUR PRODUCTS

Enhance Efficiency with HRST

Access Doors

Many styles of access doors require two people to open and need frequent repairs to the door frame studs.

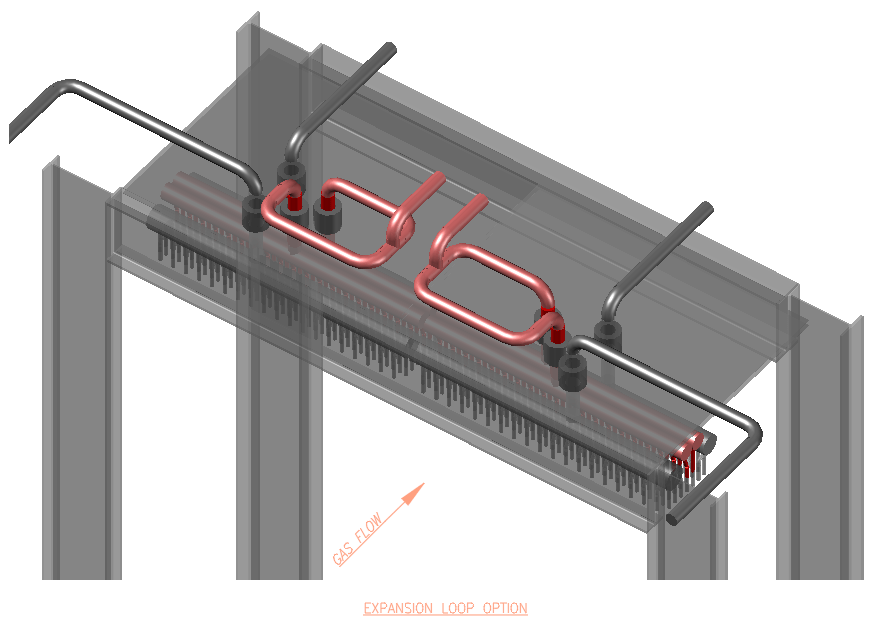

Gas Flow Components

HRSGs and power boilers utilize baffling, tube ties, flow distribution grids and vanes to help direct gas flow through the heat transfer.

Liner System Upgrades

HRSGs and many styles of Waste Heat Boilers have an internal Liner & Insulation system to protect the outer casing from the hot exhaust gas.

Pipe Penetration Seals

We can customize all our pipe seals for your specific application. HRST has developed several retrofit pipe penetration seals to replace.

Pressure Parts

HRST QuenchMaster® Air Attemperation System

HRST FlexTune™ HRSG Pressure Control System

HRST ShockMaster® Economizer