- Home

- Proccess Boilers

Proccess Boilers

Process Boilers

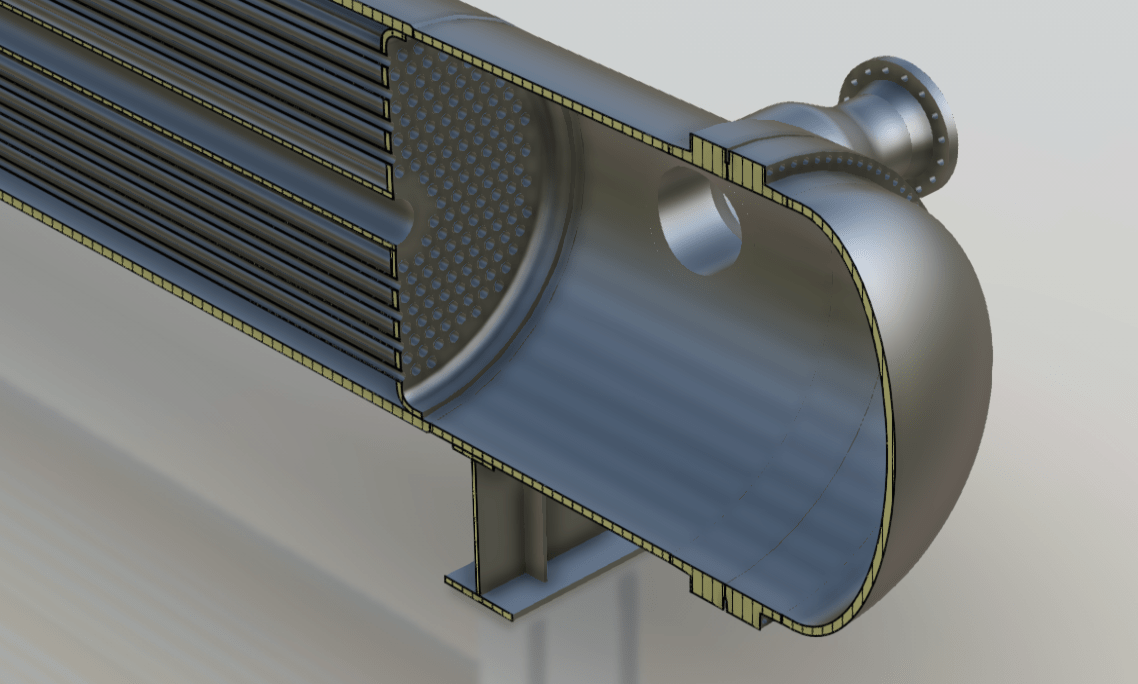

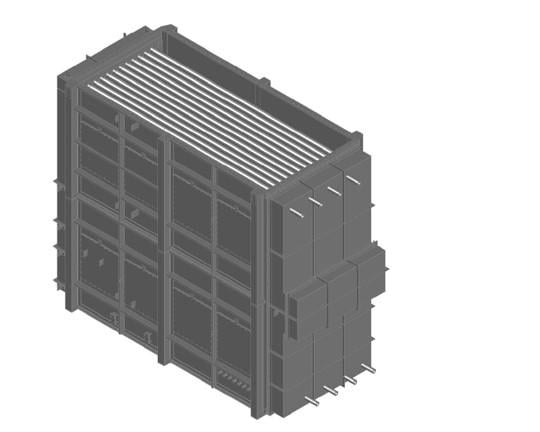

We specialize in technical services for Waste Heat Boilers (WHBs), Process Gas Boilers (PGBs), and Package Boilers for the power, refining/petrochemical, and process industries. Our team of engineers, technicians, and designers can inspect, analyze, and solve your facility’s boiler problems. We combine our experience from field inspection, engineering and design to analyze how modifications affect system operation and determine component operating limits with our proprietary modeling software, HRST Performance Pro.

For more information on our services, contact your nearest representative.

Or contact our Director of Process Boilers, Evan Almberg, P.E., at [email protected]

Click to request an informational booklet on our solutions: HRST Waste Heat and Process Gas Boiler Solutions.