- Home

- Pressure Part Upgrades

Pressure Part Upgrades

Pressure Part Upgrades

Spare Tube Stock Box

Be ready for your next tube leak by having an HRST engineered box of spare tube stock.

- Save time

- Fix leaks on the spot

- No hassle of expedited sourcing

- Minimize inventory costs & space requirements

- Organized storage of labeled tubes with Material Test Reports

- HRST will do the review and analysis of your HRSG to select the proper tube pieces for the entire HRSG

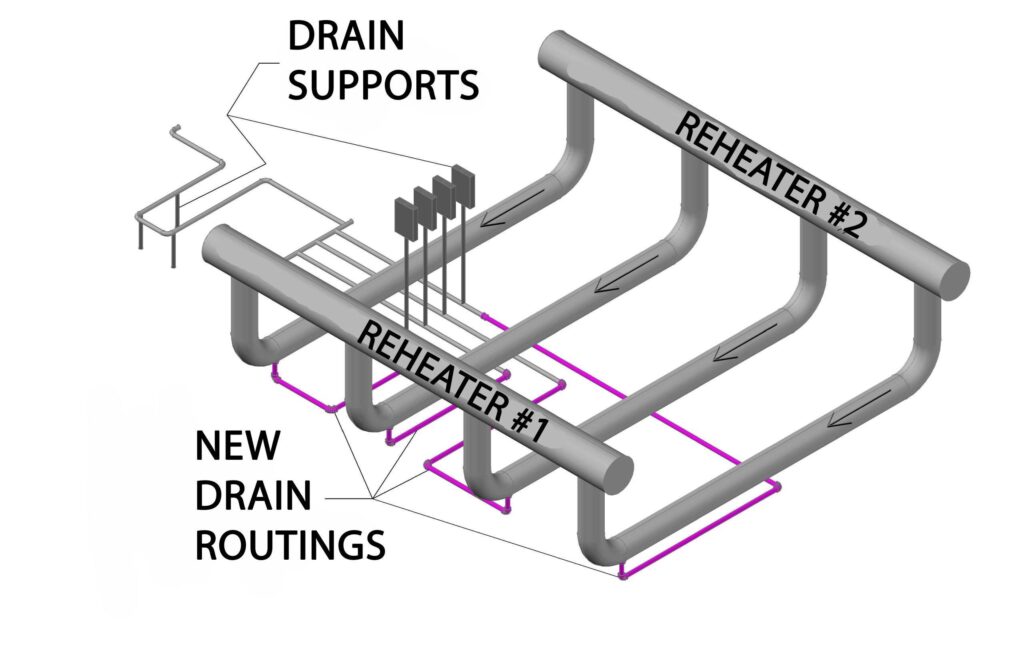

Superheater/Reheater Drain System Upgrade

Current drain system have you feeling drained? Upgrade to an HRST Drain System.

- Redesign existing pipe route layouts that are problematic

- Sized for proper condensation removal and rates during shutdowns, trips, and starts

- Drain pipe routing with improved flexibility

- Better instrumentation and controls to detect and avoid condensation

- Integration of current ASME Boiler & Pressure Vessel code upgrades where possible

Steam Drum Door Upgrade

A retrofit steam drum manway door kit includes everything needed to install and use the drum door.

- Door system design eliminates the need for stud hot re-torqueing

- Door design, closing hardware, and closing procedures reduce the risk of gasket leaks from poor alignment

- Applicable for steam drum elliptical manways

- Internal manway door and bolt plates or strongbacks specifically designed for your application

HRST ShockMaster Economizer®

- Patented design promotes uniform water flow and temperatures across each tube panel, minimizing pressure part stress

- Excellent for low-load performance

- Excellent for cycling HRSGs

- Design allows complete venting prior to start-up

- Shop modularization for short retrofit outages

- Compatible with partial economizer replacements

Steam Spargers

Spargers done incorrectly will generate frightening and damaging water hammer. HRST provides engineered spargers for freeze protection or for maintaining a level of steam pressure.

Economizer Return Bend Failure Mitigation

Are your experiencing repeated failures in the upper return bends? Return bends looped over a support are a nightmare to repair. HRST can design a modified support system to prevent such failures.

Solutions:

- Evaluate the original design

- Inspect for problem indicators

- Change the economizer support strategy to manage thermal expansion and start-up transients

- Eliminate excessive stress on return bends

Features:

- Eliminates return bend crushing failures

- Makes (damaged) return bends accessible should repairs be necessary

- No pressure part modifications

- Innovative retrofit strategy that simplifies field installation wo

4 Bent Tubes for HP Evaporator

Pipe liner for Reheater Desuperheater

“We had a short outage and needed a pipe liner for a reheater project. The attemporator was broken off and we needed expert recommendations for repairing the nozzle. HRST, Inc. was just great. They really helped us out a lot. They sent us a new liner right away. We had several questions about fitting the liner and we needed several on-site modifications. What impressed me was how helpful HRST, Inc. was throughout the entire process. All of our questions were answered immediately and we got all the help we needed to make this project work for us. I would definitely recommend your company to any facility with a similar need. We certainly plan on working with your firm in the near future.”